Automated heavy metal recovery systems in construction sites

Business Idea Concept.

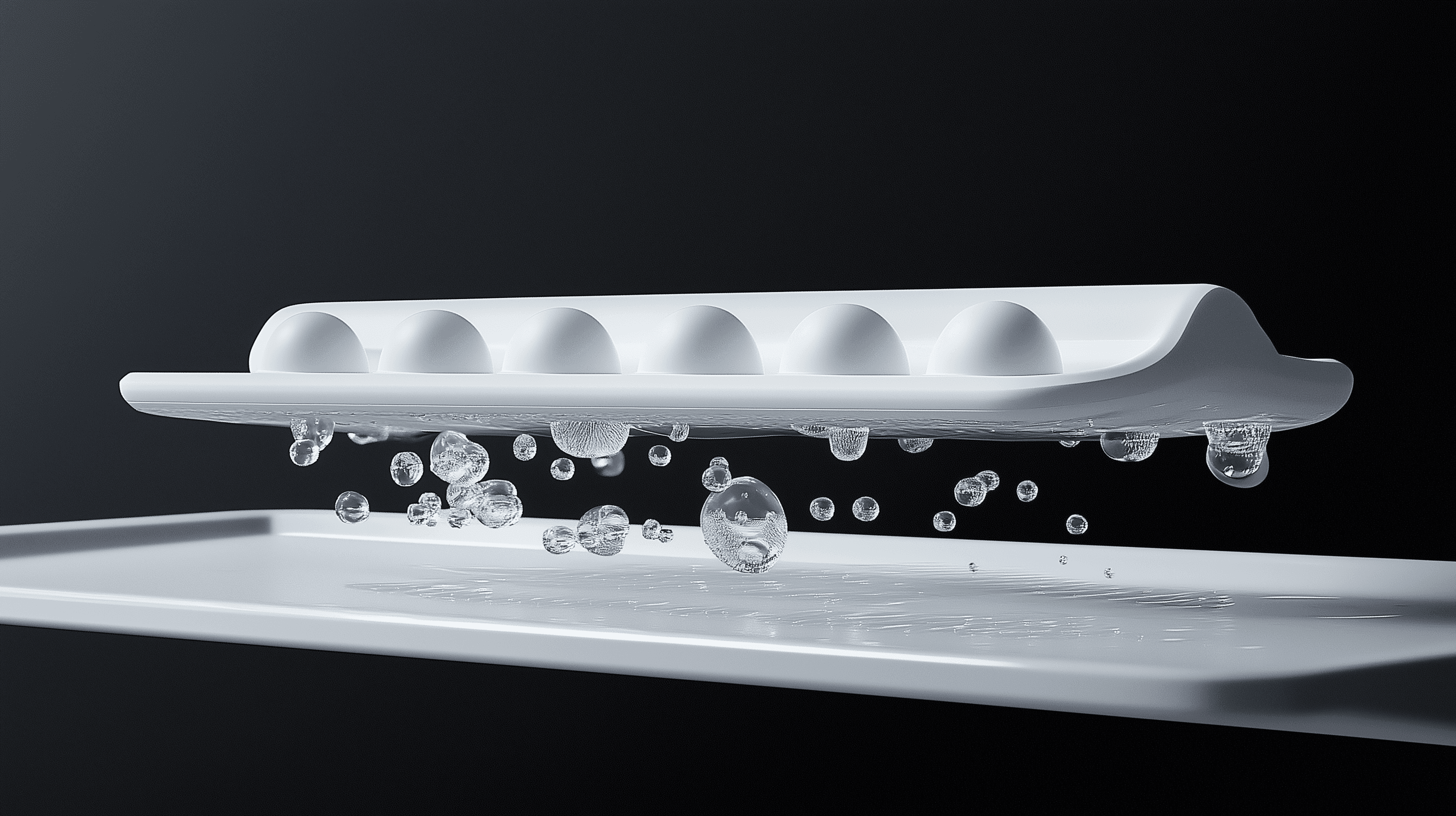

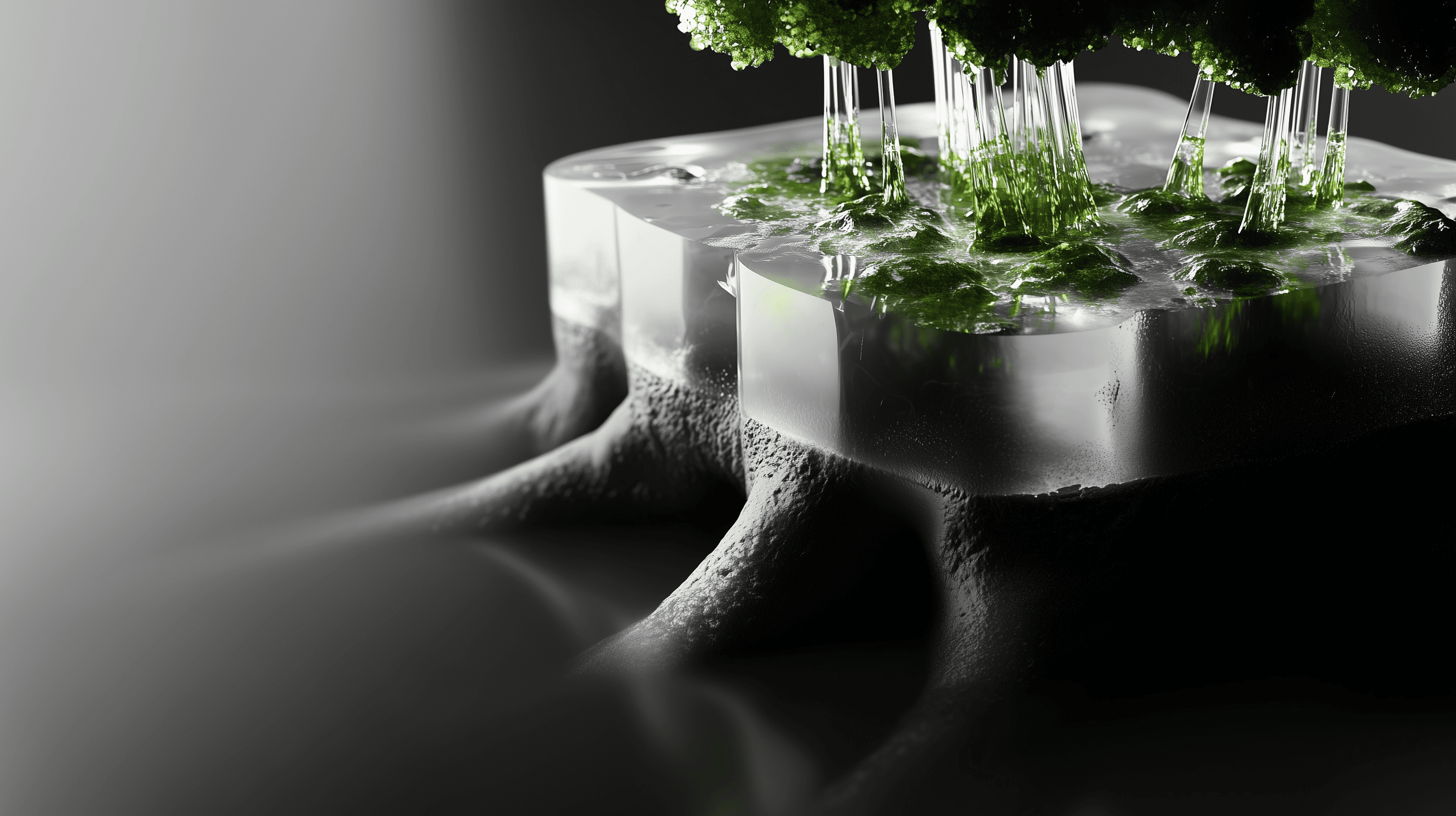

The Automated Heavy Metal Recovery Systems address a critical issue in construction and environmental remediation by offering an efficient, low-cost solution for heavy metal contamination in soil. This innovative technology uses recirculating soil washing and filtration to remove harmful metals like copper and lead, ensuring both safety and sustainability in construction projects.

With a rapid treatment time and energy-efficient design, this system not only meets regulatory standards for soil safety but also preserves essential nutrients for agricultural use. By implementing these automated systems, construction companies can reduce remediation costs, minimize pollution, and enhance their sustainability practices, ultimately transforming soil management in the industry.

Innovation at the Core.

Technology Readiness Level

User Persona.

Key Features.

Market Size.

MVP Cost Short

Breakdown.

Research & Development

$40,000 - $70,000

Component/Material Sourcing

$20,000 - $30,000

Design & Branding

$10,000 - $20,000

Initial Production / Build

$50,000 - $80,000

Testing & Certification

$30,000 - $50,000

Total

MVP ready for demonstration and pilot studies

$2.0M*

*These are rough estimates. For more precise calculations, generate a Business plan based on the chosen Business Idea.

Major Competitors.

These companies provide soil remediation services, but their methods often involve higher costs, longer timelines, and potential for secondary pollution.

Remedi8

Clean Earth

Environmental Remediation Technologies, Inc. (ERT)

Soil Solutions Group

Electrokinetics, Inc.